Tilt-Up Building Retrofits

Background

Older tilt-up concrete wall buildings have been categorized, based on past earthquakes, as being potentially hazardous and prone to significant damage, including possible collapse, in a moderate to major earthquake. It is highly recommended, and depending on the jurisdiction, mandatory, for such buildings designed in accordance to building codes in effect prior to 1976 to be retrofitted. Jurisdictions with such mandatory ordinances are City of Los Angeles (Division 91), County of Los Angeles (Chapter 95), and City of Burbank (Ordinance 3512). The purpose of the implementation of these ordinances is to reduce the risk of death or injury that may result from the effects of earthquakes.

Tilt-up structures tend to have very light plywood sheathed roofs in comparison to the much heavier concrete wall panels that support them. When exposed to moderate seismic excitation, the nail connections between the plywood sheathing and the concrete walls are susceptible to failure. In this type of failure mode, the concrete walls are free to separate from the roof sheathing causing the roof to collapse. Subsequently, the walls will collapse, as the roof is no longer there to stabilize the walls.

Retrofit Mechanics

There are four major aspects to the retrofit of a tilt-up concrete wall building:

Sub-purlin to Wall Anchorage

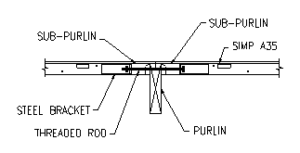

Sub-purlins are the light, repetitive, 2x members at closely spaced intervals that support the roof. Steel brackets are used to provide a positive connection between the concrete walls and the sub-purlins that reduce the risk of the walls separating from the plywood sheathing. See typical detail shown below.

Purlin to Wall Anchorage

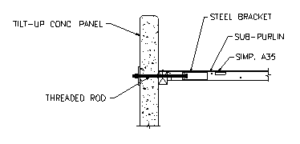

Purlins are the heavy 4x members typically spaced 8 feet apart that support the sub-purlins. Steel brackets are used to provide a positive connection between the concrete walls and the purlins that reduce the risk of the walls separating from the plywood sheathing. See typical detail shown below.

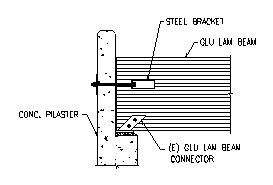

Glu-Lam Beam to Wall Anchorage

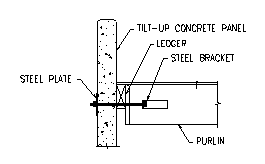

Glu-Lam beams are the main beams that support the purlins and are in turn supported by concrete pilasters or posts. Steel brackets are used to provide a positive connection between the concrete walls and the glu-lam beams that reduce the risk of the walls separating from the plywood sheathing. See typical detail shown below.

Continuity Ties

Continuity ties are achieved by adding steel brackets at interior points in the roof framing so as to tie a concrete wall with another concrete wall parallel to it. The concept here is to inhibit the ability of the wall panel to pull away from the roof by tying it back to the opposite side wall. See typical detail shown below.